Episode #631

March 6, 2021

We like things to be efficient and to do things with efficiency.

Efficiency saves energy, time, money and effort.

Efficiency is a tool used to enhance a process.

It is not an end result or a goal.

When doing repetitive operations in a project i have used different approaches.

SUBSYSTEM APPROACH:

When building a composite graphic:

Find the clip art.

Edit the art.

Store the modified image.

Repeat for all clip art elements.

Assemble the elements.

Refine the final graphic.

CONTINUOUS IMPROVEMENT APPROACH:

When building a composite graphic:

Find the clip art.

Edit the art.

Add the modified clip art into the graphic refining the overall image as i go.

Repeat for next element.

In both cases i use multiple applications with multiple windows open on my computer screen.

Searching, copying, pasting, editing, storing (saving) and refining is efficient across open windows.

With the SUBSYSTEM approach additional effort is required to store the edited clip art elements prior to final assembly.

The natural flow of the project is interrupted by its looping nature.

With the CONTINUOUS IMPROVEMENT approach the work on the final graphic flows from element to element. The graphic overall evolves as it is assembled. Each evolution informs the editing of the next clip art element.

Time is not lost to intermediate storage, revisiting of the project or artificially imposed looping of tasks.

Also, there is more opportunity for exploration as each edit presents possibilities for the next edit.

CONTINUOUS IMPROVEMENT is more efficient.

It is also more creative.

A project that flows from beginning to end allows for innovative distractions.

Looping SUBSYSTEMS waste time while limiting foresight and creativity.

Some efficiencies are false conclusions.

During the great recession unemployment was high.

Employers were able to work their employees harder without raising their wages.

The profit as it related to labor was higher.

Employers said that their work force had become more efficient.

Eventually, as employees worked harder for less money, productivity was lost to low morale and their actual efficiency was lower.

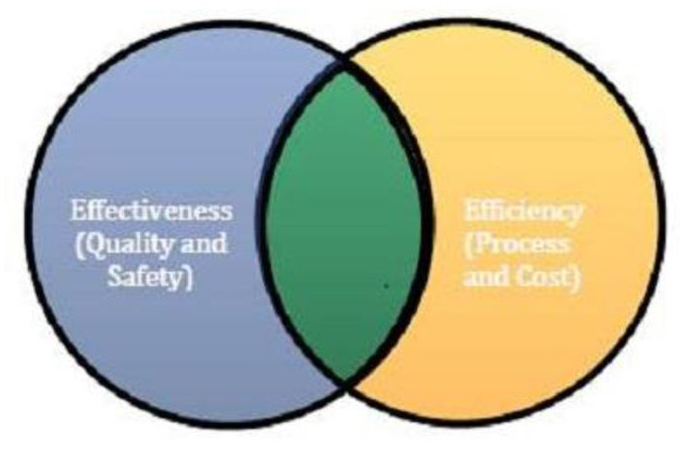

Breaking a production line down into highly specialized repetitive tasks can make product assembly more efficient. There is a sweet spot where quality and efficiency intersect. It is a balance of specialization and innovation.

A consequence of too much specialization is boredom.

There is no room for improvement or innovation in a highly specialized system.

Ironically, workers who are bored and despondent from efficiency are less efficient on the job.

“A human being should be able to change a diaper, plan an invasion, butcher a hog, conn a ship, design a building, write a sonnet, balance accounts, build a wall, set a bone, comfort the dying, take orders, give orders, cooperate, act alone, solve equations, analyze a new problem, pitch manure, program a computer, cook a tasty meal, fight efficiently, die gallantly. Specialization is for insects.”

— Lazarus Long by Robert Heinlein, Time Enough for Love.

When preparing to give a speech i make a plan.

The plan is a list of topics which will lead to efficient speech delivery.

i write the list of topics on a flash card.

Each topic reminds me of a story that i know.

i tell each story from memory so that it is fresh every time.

i reserve the right to skip or revisit a topic if that is where the speech leads me.

The overreaching story of the speech is delivered efficiently because my preparation was only a short list of topics.

It is interesting because i have the freedom to innovate.

It is satisfying because i make my point in an organic and human way.

i use efficiency as a means and not an end.

Efficiency is a tool, not a goal.

Love Lazarus Long! And watching my new assistant, Alyssa, work on the bookmark mailing, I think she went through at least 3 of your approaches to efficiency. It was a beautiful thing to watch a 9 year old experiment with efficiency!

PS. I watched and did not offer advice; she worked it out on her own. Great teaching tool in this case (though maybe not for brain surgery).

Wow, that mask making was amazing. and for different reasons the Kia factory was interesting. I would write more now, but instead I need to head over to Krispy Cream donuts.

Jeff Laun

First thing in the morning Krispy Cream donuts are warm. They used to give you one for free if all you wanted was one.